Which is right for your business - Stock or Custom Packaging?

19th Feb 2025

When it comes to using corrugated packaging for your business, one of the key considerations is whether to purchase standard stock cardboard boxes or custom made cardboard boxes. Both options offer different benefits and the right choice will depend on factors such as cost, branding, protection, and efficiency. Below, we explore the relative merits of each option to help you make an informed decision for your business.

Cost Efficiency

One of the most immediate differences between stock cardboard boxes and custom-made boxes is cost. Standard stock boxes are mass-produced, making the actual box cheaper per unit, whereas Custom boxes are made specifically for your requirement and product and so may have a slightly higher unit cost. However standard boxes only work for products that fit the standard size - otherwise the potential damage in transit will offset any savings.

Consider other cost elements too. Often more custom boxes will fit on a pallet, reducing delivery costs. So if your products would fit better in a custom box, you could be saving money!

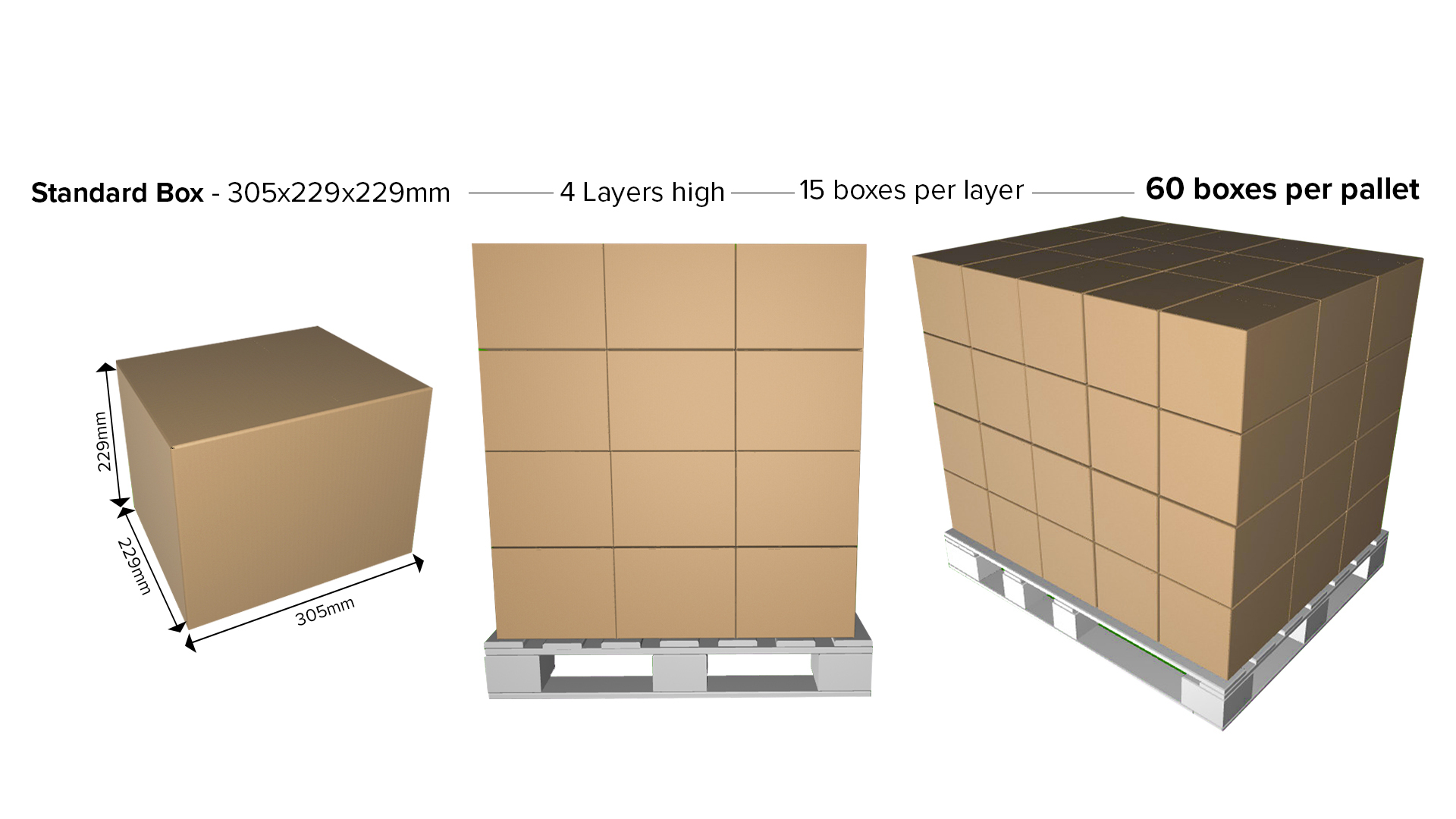

To see how this works, below we show a standard commonly used box which will fit:

15 per layer @ 4 layers high = 60 boxes per pallet ❌

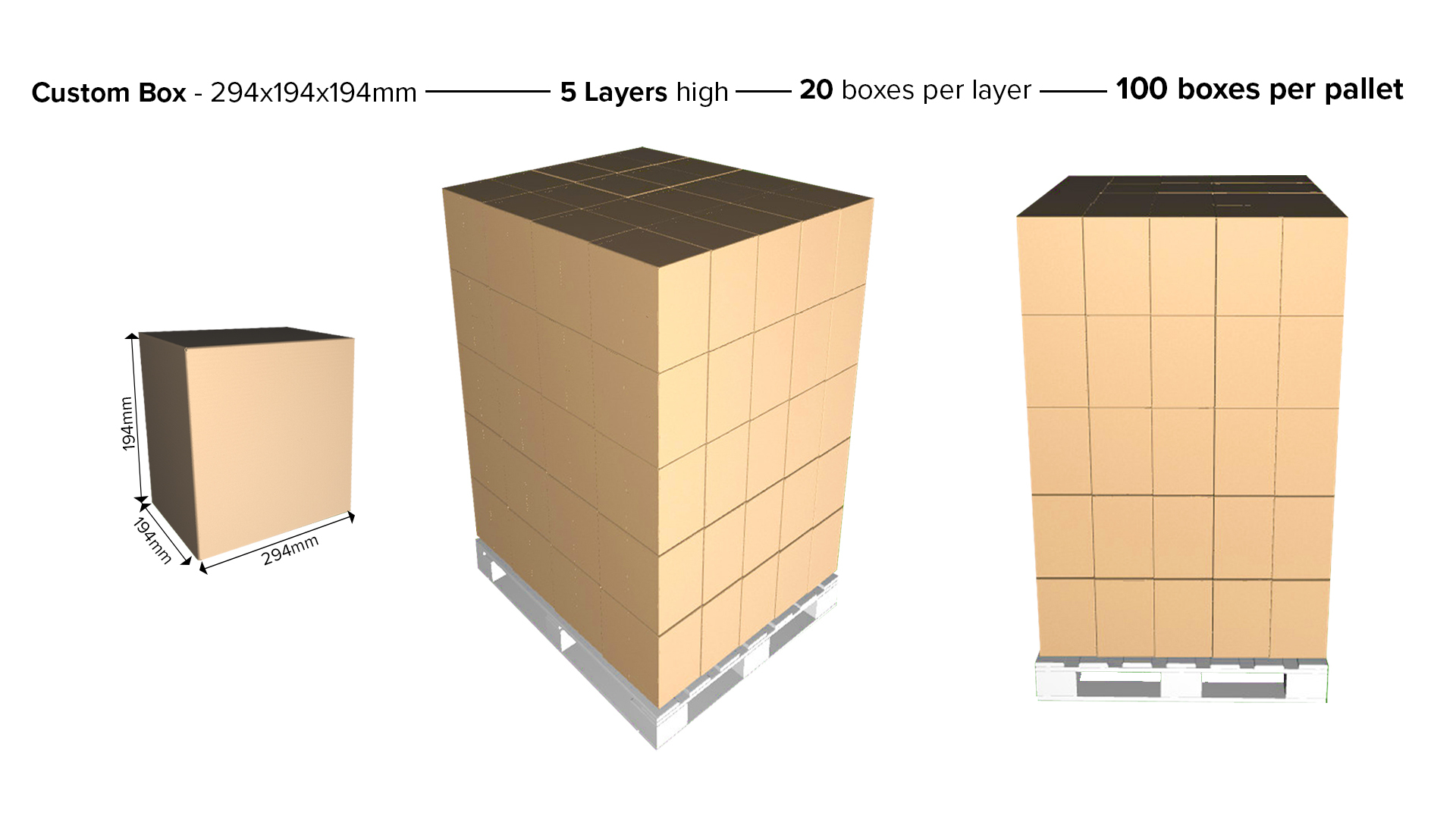

If we customise this box very slightly - 294 x 194 x 194mm - you can now fit:

20 per layer @ 5 layers high = 100 boxes per pallet✅

For a next day delivery cost of £45 per pallet, that means 0.75p per standard box, but just 0.45p per custom box, 30p per box cheaper!

And don't forget, having fewer deliveries reduces your impact on the environment too - less journeys, less resource use, less carbon emitted.

We’ll help you to consider the full cost picture, so you can make the right choice.

Branding and Customer Perception

Branding is a critical component of modern business strategy, and packaging plays a significant role in shaping customer perception. Standard stock boxes, while practical, offer little in the way of branding opportunities. Companies that use them may have to rely on stickers, printed labels, or external branding materials to convey their identity.

Custom packaging, however, allow businesses to integrate their branding directly into the packaging. With the ability to print up to two colours, for branding, logos and other information, and create custom die-cuts, bespoke packaging can help create a memorable unboxing experience. This is particularly important for e-commerce businesses and premium brands that want to differentiate themselves in a competitive market.

But it apples to other businesses too. When you want to include vital handling or product instructions for your customers, bespoke packaging let's you print on your packaging.

Protection and Durability

The level of protection required for shipping and storage is another important factor when choosing between stock and bespoke boxes. Standard stock boxes are designed for general use and may not always provide the ideal fit or structural integrity needed for fragile or uniquely shaped products. This could result in increased damage rates, leading to higher return and replacement costs.

Custom boxes, on the other hand, are specifically designed to fit and protect the product they are intended for. Businesses dealing with delicate, expensive, or irregularly shaped goods may benefit from the added protection that custom packaging provides. Custom inserts and reinforced structures can also be incorporated to minimise movement and breakage during transit.

Efficiency and Availability

Stock cardboard boxes have the advantage of being readily available, meaning businesses can quickly source them without long lead times. This is ideal for companies that need packaging solutions on short notice or those that operate with unpredictable demand.

Custom boxes can require a slightly longer lead time for design, production, and delivery. This really means considering packaging requirements and planning ahead to ensure custom packaging is always available when needed.

It is worth checking lead times with your packaging supplier though – for example, at ASC Direct, we hold stock so we can provide custom boxes quickly.

Both standard stock cardboard boxes and bespoke made cardboard boxes have their merits, and the right choice depends on the specific needs of a business. Standard stock boxes have a low individual unit cost and are readily available but other factors may render them unsuitable. In contrast, bespoke made boxes offer enhanced branding, superior product protection, and a tailored fit and can actually be a lower cost when all aspects of the product and packaging are taken into account.

Ultimately, the decision should align with the company’s budget, brand positioning, and operational needs to ensure the best packaging solution for their products and customers. To find out more about the best packaging option for your business, please get in touch.

James Palfrey-Smith is the Commercial Manager at ASC Direct with extensive experience in both operations and sales. James is passionate about solving packaging problems, delivering fast customer support, and building lasting relationships. Outside of work, he enjoys outdoor activities like hiking and skiing. A fan of real ale and business podcasts, he continuously seeks personal and professional growth.

Find James on Linkedin

Find out more about James